CRITICAL SPACES HAVE CONSTANTLY EVOLVING, DEMANDING REQUIREMENTS.

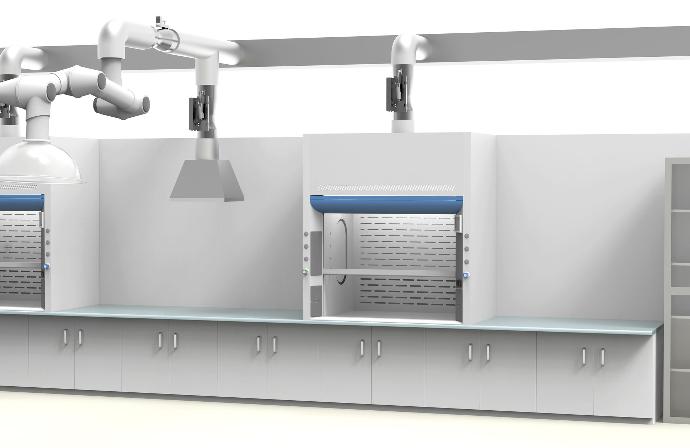

Hood Controls

The hood controls system consists of sash position sensors, a face velocity monitor / alarm annunciator, and a variable volume venturi air valve. The face velocity controller is typically mounted on the venturi valve. The sash sensor is mounted on the top of the hood and attached to the sash. A factory calibrated variable venturi valve provides accurate and stable exhaust air flow control and hence face velocity. The fume hood monitor is mounted on the front side panels of the hood to confirm safe hood operation, alert the user of potential system malfunctions, and provide manual override functions. The hood control system accepts sash sensor inputs and controls the fume hood exhaust air flow to maintain the set constant face velocity to provide virtually instantaneous response. In about one second from when the sash comes to rest, the air flow is modulated to within ±5% of the target air flow to ensure constant fume hood face velocity. The fully distributed microprocessor-based controller of the hood control system is capable of operating other air flow and PID control loops in the lab. One hood control system is required for each fume hood for maximum user safety.

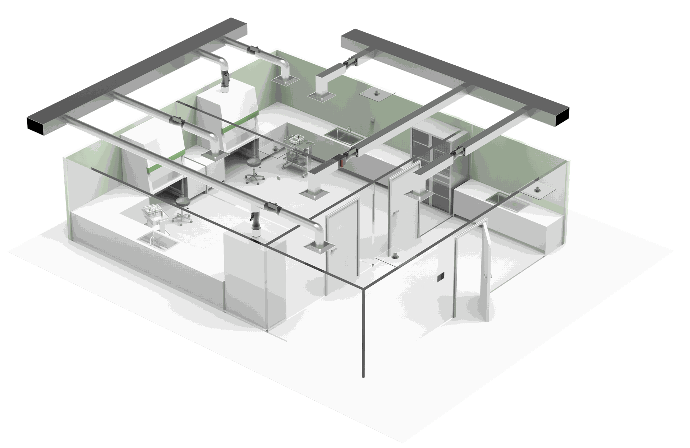

Room Controls

Maintaining accurate and constant pressurization in your room, the secondary barrier isn’t a nice to have, it is a must. Potential contaminants in critical spaces must be contained to ensure the safety of unaware occupants in adjacent spaces aren’t negatively affected. AirGenuity’s matched supply and exhaust venturi valves ensure matched speed of response and accuracy to maintain room pressurization under all operating conditions.

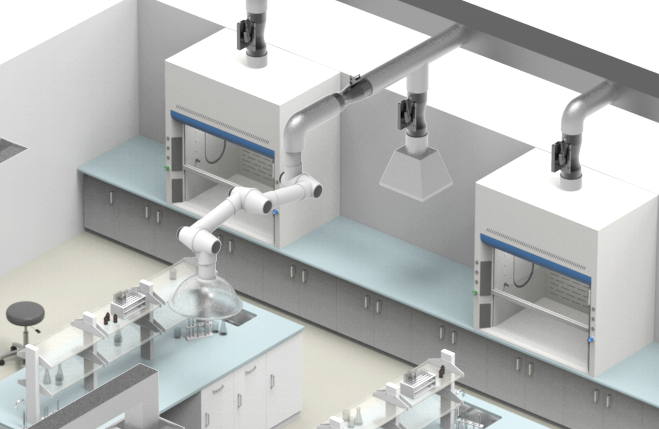

Snorkel Control

Snorkels which run

continuously can drive significant energy usage by increasing the total

exhaust. Strategies which reduce flow such as on off operation or timers can

ensure occupant needs and lab safety are achieved while simultaneously reducing

operational carbon and costs